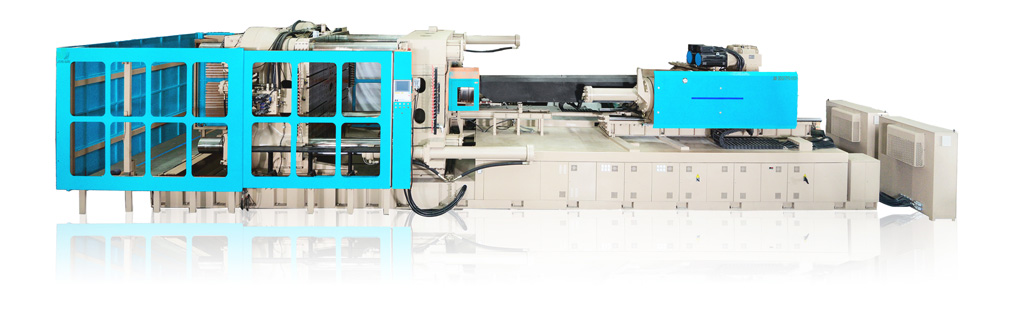

TP Series

TP Series

2-Platen large injection molding machine

- Mold height and clamp stroke customizable according to customer require

- Free combination of injection units and clamping units

- Platens size and tie-bar distance customizable

| Model Name | Unit | 850TP | 1300TP | 1450TP | 1650TP | 2000TP | 2300TP | 2700TP | 3200TP | 3500TP |

|---|---|---|---|---|---|---|---|---|---|---|

| Clamping Tonnage | tons | 850 | 1300 | 1450 | 1650 | 2000 | 2300 | 2700 | 3200 | 3500 |

| Tie bar distance (WxL) | mm | 1100 x 1000 | 1400 x 1300 | 1520 x 1350 | 1650 x 1550 | 1800 x 1600 | 1900 x 1700 | 2100 x 1900 | 2200 x 2000 | 2200 x 2000 |

| Platen size (WxL) | mm | 1620 x 1520 | 1990 x 1890 | 2130 x 1960 | 2300 x 2200 | 2500 x 2300 | 2680 x 2480 | 2920 x 2720 | 3120 x 2920 | 3180 x 2980 |

TP Features

Compact & Saving

- The Unique 2-platen Clamping Mechanism Reduce the floor space over 21% than conventional 3-platen machine.

- The hydraulic oil is reduced to less than 50% of conventional machine. As design on dividing the clamping cylinders into Booster cylinder for mold movementand High pressure cylinder for mold locking.

Rigid Mechanism

- High intensive Box-Like structure casting platen with solid ribs which optimum rigidity with 3-D design and Finite-Element Anlysis.

The clamping force is perfectly distributed and minimizes mold deflection and stress & wear on the mold parts. - High Pressure locking cylinders are independent and not integrated with the casting platen. Without potential oil leaking risk caused by casting holes.

- Mold high adjustment done by direct hydraulic instead of adjustment mechanism.

Less mechanical parts imply less malfunction and less maintenance. - Powerful mold opening force design, opening force is 9% of mold closing force.

More Accurate

- Mold open/close drive by 2 booster cylinder in angular position.

During travel, the moving platen is supported by large / solid steel / adjustable sliding shoe. This allow the moving platen travel smooth, steady and guarantee the platen absolute parallelism. - JONWAI patented Mold locking semi-circle intermeshing nuts provide more accurate and faster nuts fixed position.

More flexible and modularity

- Mold height and clamp stroke could be increased and customizable according to customer require.

- Platens size and tie-bar distance could be increased and customizable according to customer require.

- Free combination of injection units and clamping units big benefits for customers procurement.

Faster Production

- Mold high adjustment done by direct hydraulic cylinder instead of mold high adjustment mechanism easy and fast on mold.

- High pressure mold locking by 4 sets of semi-circle intermeshing nuts mechanism which drive by 4 sets of high pressure hydraulic cylinders.

- Semi-circle intermeshing nuts mechanism and high pressure hydraulic cylinder is separate and no contact with tie-bar.

This design allow the semi-circle intermeshing nuts fixed position simultaneously during mold fast close. By this unique design the cycle time was reduced effectively (JONWAI patented design). - When semi-circle intermeshing nuts fixed position, only high-pressure cylinders and intermeshing nuts working, the total weight is light and operating time is shorter. By this unique design the cycle time was reduced effectively(JONWAI patented design).

Easier operation

- High pressure mold locking hydraulic cylinders are on the movable platen.

Fixed platen design is tidy and neat, which leaves more space for operating. - Tie bars and high pressure mold locking hydraulic cylinders are detached without contact, maintenance easier.

- Independent clamping cylinders are not integrated with platen casting, replace oil seals easier.

- Tie bars and clamping cylinder are detached without contact.

No need to dissemble tie bars while replacing oil seals.

No need to disassemble cylinders while changing tie bars.

AC Synchronous servo power saving system

TP series optional with AC Synchronous servo power saving System integrating all of the excellent features such as energy efficiency water saving, hydraulic oil saving, quiet operation and precision molding.

TP Application